Features

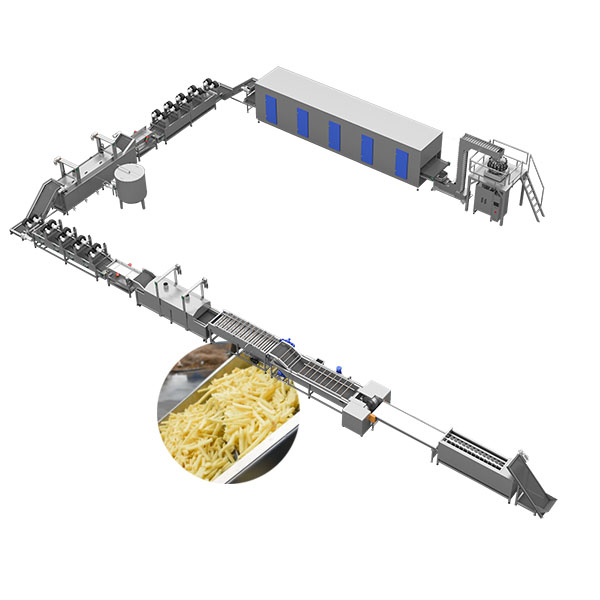

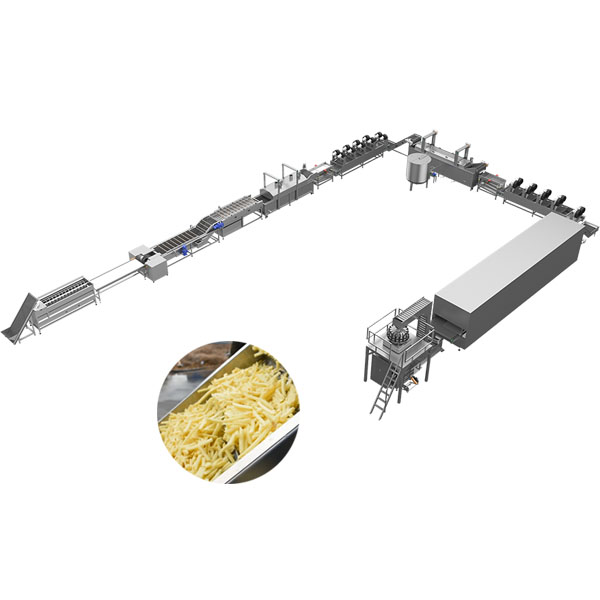

Fully Automatic French Fries Production Line Introduction

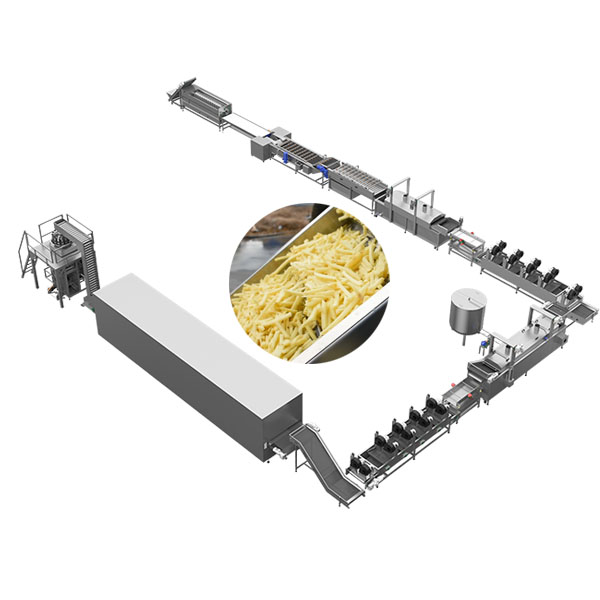

Complete fries line fully realizes automatic production, and simplifies and condenses French fries production process, and designs and develops with reference to customer feedback. The production capacity is 500kg/h, the installed capacity is 450kw, the water consumption is 1 ton/h, space is about 800 square meter, and the quality of the produced French fries has reached the advanced level in foreign countries. The french fries production line equipment can be adapted for production of frozen French fries.

This is a large capacity production line used for manufacturing good quality frozen French fries. Frozen French fries can be kept longer than potato chips that are the reason why some noshery and restaurant like cafeteria, McDonald and KFC cook French fries to sell. And also we supply small scale french fries production line for selection.

Different French Fries Production Line Capacity

Quick-frozen French fries are generally the finger chips, which are made with pure potatoes. The complete set quick-frozen fries production line contains more equipment, including potato peeling washing machine, bubble washing machine, blanching line, pottao cutting machine, French fries fryer, air cooler, deoiling line, quick freezing machine, etc.

Different French Fries Production Line Capacity

| Model | Capacity | Power | Floor Space |

| GGF-100 | 100 kg/h | 71 kw | 33.25m(L)*2.3m(W) |

| GGF-300 | 300 kg/h | 180 kw | 48m(L)*3m(W) |

| GGF-500 | 500 kg/h | 246 kw | 58m(L)*3m(W) |

| GGF-1000 | 1000 kg/h | 335 kw | 91m(L)*4m(W) |

Frozen French Fries Production Process

Raw material feeding -- Cleaning peeling -- Selecting -- Material feeding -- French fries cutting -- Rinsing -- Blanching for protecting color -- Removing excess water -- Frying -- Removing surface oil -- Conveying -- Packing.

Quick-frozen French fries are generally the finger chips, which are made with pure potatoes. The complete set quick-frozen fries production line contains more equipment, including potato peeling washing machine, bubble washing machine, blanching line, pottao cutting machine, French fries fryer, air cooler, deoiling line, quick freezing machine, etc.

Frozen Frozen French Fries Manufacturing Process Video

Features of Automatic GELGOOG French Fries Production Line

- Fully automatic from potato washing to packing

- All machines of this whole production line are made of stainless steel material.

- Size of French fries can be cut from 2-10 mm, adjustable

- Change French fries cutting machine, can be used for making potato chips.

- 6-8 workers are enough, saving manpower.

Turnkey Production Line for Frozen French Fries Processing Machinery

Technical Data

| Product Name | Frozen French Fries Line |

| Model | GGF-500 |

| Place of Origin | China |

| Brand | Gelgoog |

| Raw Material | Fresh Potatoes |

| Final Product | Frozen French fries |

| French Fries Size | Customized |

| Capacity | 500 kg/h |

| Machine Material | Stainless Steel 304 |

| Size | Length 58m*Width 3m |

Related Products

: sherry@gelgoog.com

: sherry@gelgoog.com  : 0086-15515573212

: 0086-15515573212